Demanding logistics, complex change management and a high level of documentation - modern plant construction offers many starting points for further increasing efficiency. Powerful planning software for plant engineering significantly simplifies your daily work.

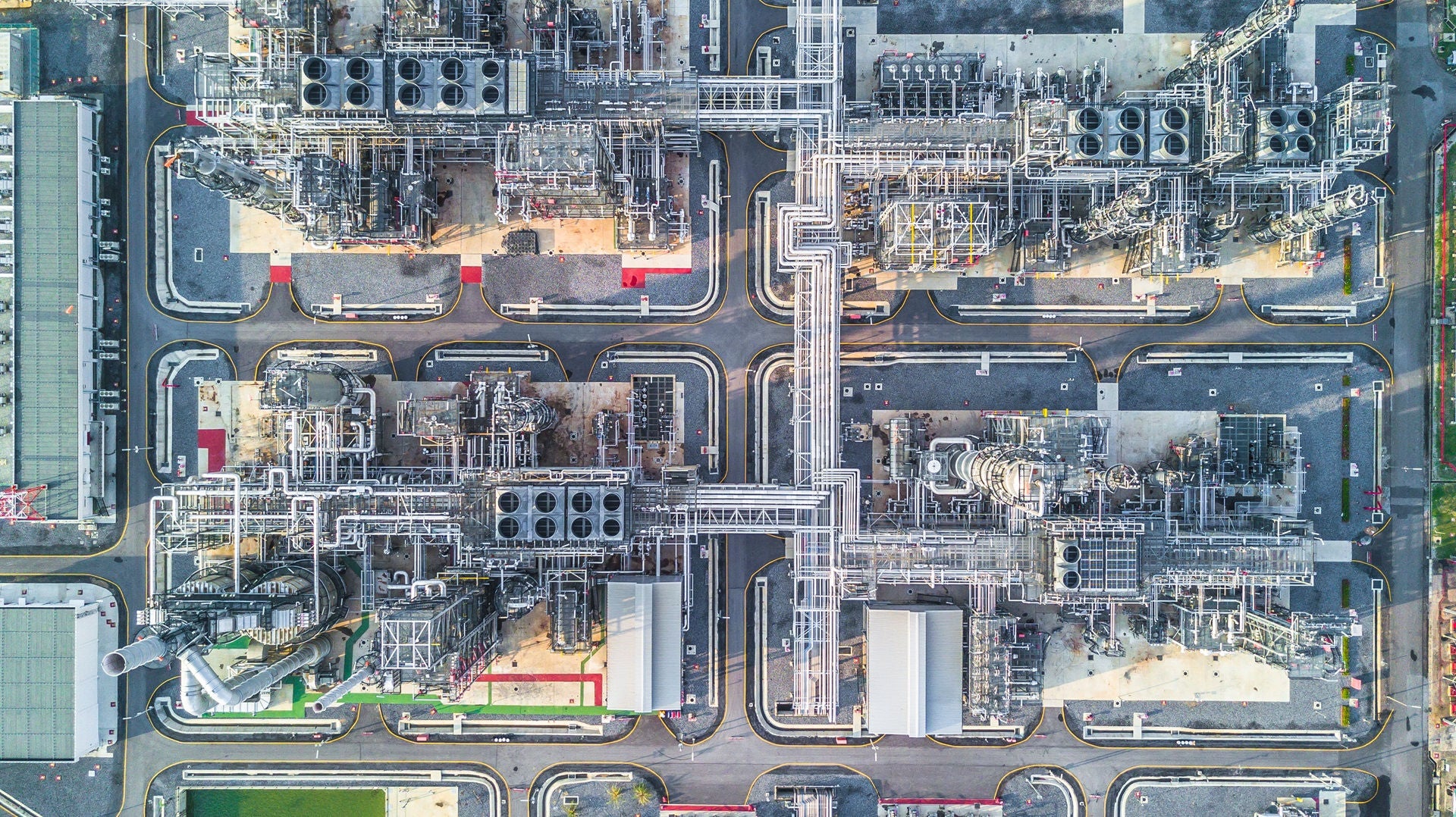

CAD software in plant construction enables precise 3D models of industrial plants. This improves planning, engineering and maintenance, optimizes the use of resources and minimizes errors. The virtual representation increases efficiency and safety, which leads to more cost-effective projects.

PDM and PLM also play a central role in plant construction. They enable the efficient management of product information and ensure seamless collaboration throughout the entire life cycle. These systems optimize processes, minimize errors and increase overall efficiency.

Cideon supports you in implementing productivity-enhancing measures with intelligent, digital and sustainable solutions. We implement software for plant construction and also offer individual software development and various consulting services on request. You can rely on our many years of experience!