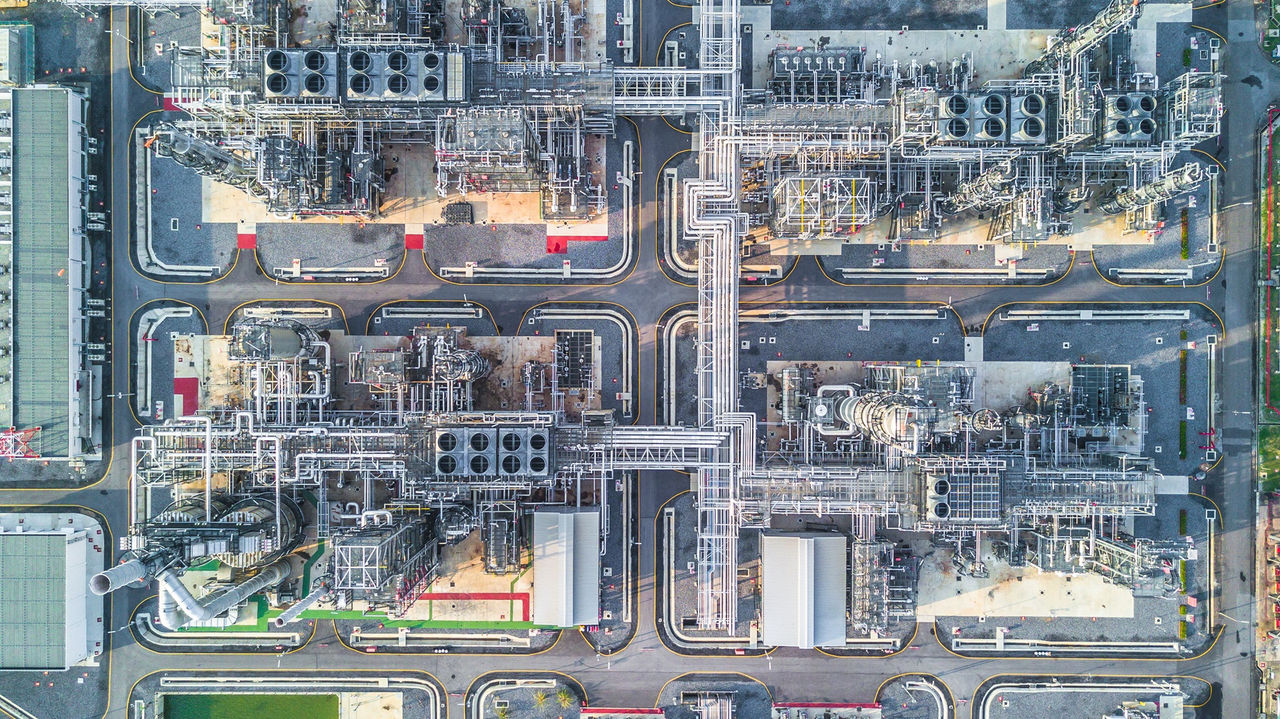

Layout and factory planning confronts companies with a variety of challenges. Efficient use of available space, optimized work processes and technological integration are crucial. Here we present you some of the challenges.

Optimize Factory Layout and Production Processes with a Digital Project Planning and Scheduling Process

Whether new planning, planning for repurposing or revitalization of production plants and manufacturing facilities: machine builders, system integrators and factory operators/planners have to deal with demands for reduced time-to-market, more flexibility and higher availability on a daily basis.

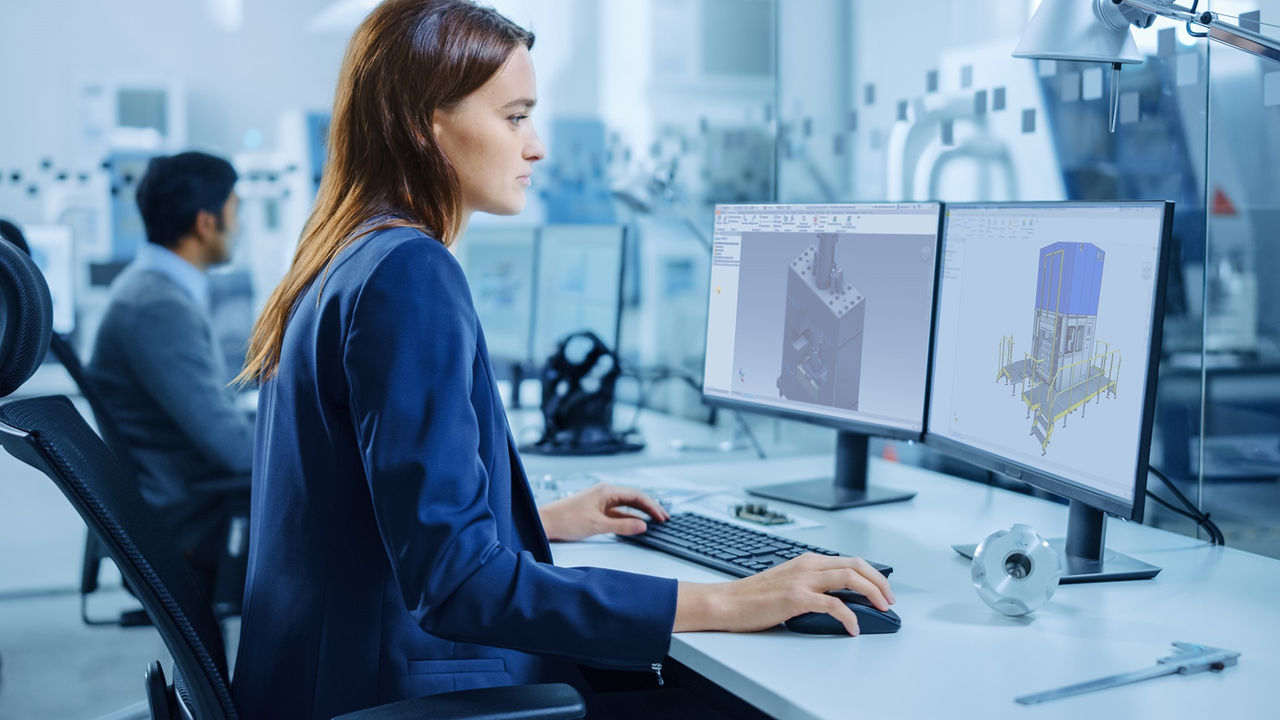

With an end-to-end digital project planning and design process, you can optimize existing workflows from concept layout and detailed planning to communication processes, validation and implementation. Thanks to realistic simulation of your production processes, you can identify bottlenecks in production at an early stage and respond flexibly to trends. This will increase your offer and order rate. Efficient layout planning programs and modern factory planning software increase the quality of your planning.

Cideon will be happy to advise you and provide you with conflict-free, efficient and successful project and layout planning using efficient factory planning software and layout planning programs.

Machine builders, system integrators and factory operators/planners need to meet the challenge of quicker time-to-market, increased flexibility and higher availability on a daily basis, whether for new planning, repurposing or revitalizing production plants and manufacturing facilities.

With its factory design concept, Cideon provides a solution for conflict-free, efficient and successful project and layout planning.

Challenges in Factory and Layout Planning

Solutions for Your Factory and Plant Layout

Cideon's factory design concept gives factory operators (planners), system integrators and machine builders simple tools and a quick workflow.

Advantages of Layout and Factory Planning

Fast and high-quality creation of layouts

Factory Design offers the optimal solution for layout creation with simultaneous high presentation quality. For machine builders, integrators, special purpose machine builders and factory designers, Factory Design provides a standardized approach, significantly reducing frictional losses, from the sales/concept phase to realization/assembly and operation.

Benefits for Machine Builders and System Integrators

Benefits for Factory Planners and Operators

FAQ about Layout and Factory Planning

Digital layout planning enables workflows to be optimized, from the concept to the implementation phase.

Cideon offers software solutions and services that improve the entire digital project planning and scheduling process. This leads to an increased quotation and order rate. Our services include planning and process analysis, PDM integration, laser scanning and photogrammetry. We respond to your individual requirements and wishes. Simply get in touch with us.

The challenges include increasing complexity, growing data diversity and the need for improved collaboration. In addition, the holistic view of the product and product life cycle is becoming increasingly important, which is why new possibilities in planning, training and sales visualizations should be used.

The benefits for machine builders and system integrators include an increased quotation & order rate, efficient planning and improved collaboration. Factory planners and operators benefit from improved production planning, interoperability between production and building planning, and digital transformation in collaboration.

The integration of PDM enables efficient data management in the layout and project planning phase by making it easy to find relevant layouts and assets.

5 Good Reasons for Digitized Factory and Layout Planning

Improve your quotation, layout, design and production phases with consistent data. You can also benefit in the spare parts and service area. We reveal 5 good reasons for digitized layout planning.

Why Cideon?

Cideon advises and supports companies in optimizing their product development processes - from conception and engineering to production and service. We stand for:

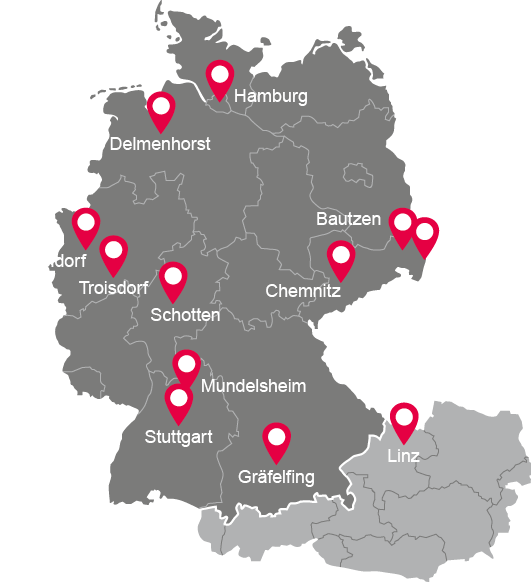

Cideon Locations

Cideon Headquarter

CIDEON Software & Services GmbH & Co. KG

Lochhamer Schlag 11, 82166 Gräfelfing (Germany)

Other Locations