Cideon interface solutions enable reliable and automated data exchange between your CAD/PDM applications and SAP. Duplicates and data entry errors are eliminated. We support you in the selection of interfaces according to your system landscape and requirements. Just get in touch with us!

This enabled the use of new functionalities for even better performance, which were previously lacking in the old ERP environment. Both the complex data migration and the implementation of the update for the SAP ECTR interface proved to be a real challenge for Hochland Natec.

The successful collaboration between Cideon and Hochland Natec shows how a modern IT infrastructure can be implemented that meets the requirements of mechanical engineering, strengthens teamwork in collaborative networks and develops new tools.

Agile Response to Change

The German mechanical engineering industry is currently facing a number of challenges. Too many workarounds, a lack of automation, and complex process landscapes are among the biggest obstacles on the road to a digital future. These obstacles are accompanied by system outages and a lack of updates for legacy IT systems. Further complicating matters is the lack of adequate data connectivity and the lack of broadband technologies to transfer large volumes of data. All this must be taken into account in digital engineering and in the management of all resources. Hochland Natec GmbH recognized these challenges at an early stage and transformed them into competitive advantages and growth opportunities with analytical potential and organizational skills.

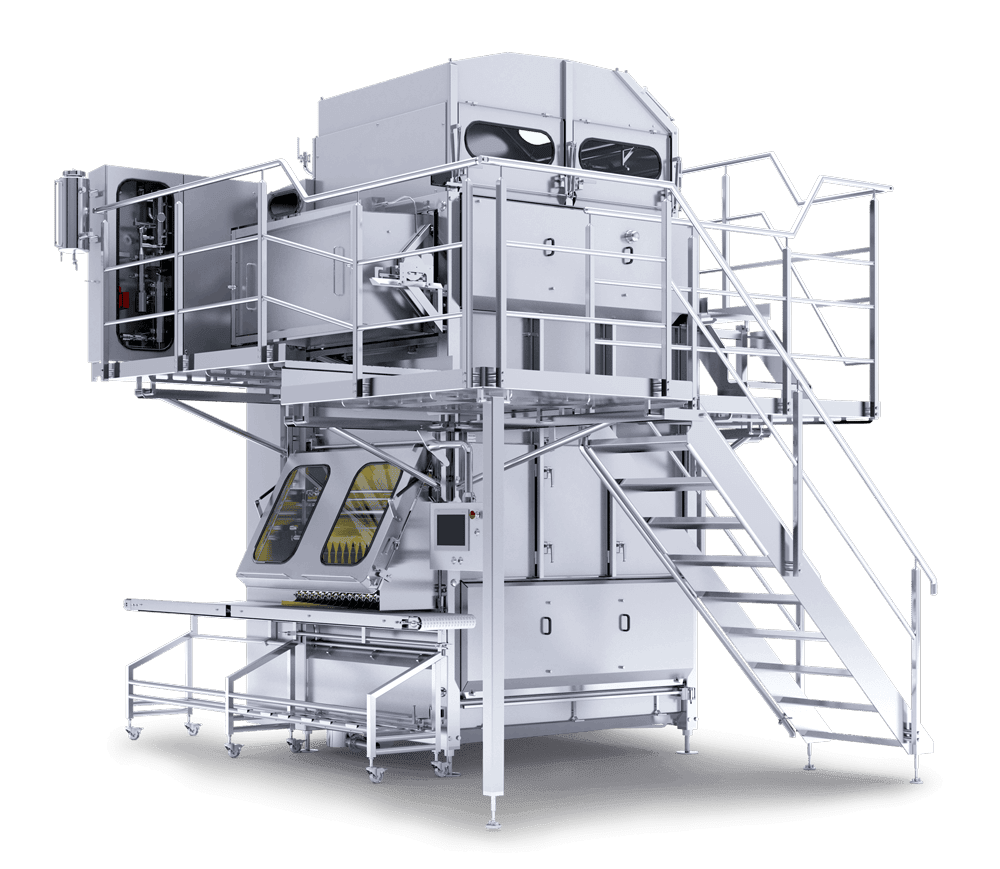

Hochland Natec impresses with its competitive delivery times of arounwd one year as a plant manufacturer. The company also focuses on innovation and the continuous expansion of its product range. As part of the "S/4 Future Project", as it is known internally, all business processes throughout the Hochland Group were analyzed and, in some cases, redefined to meet customer needs. To this end, SAP S/4HANA was to be implemented in the entire Natec Network, consisting of three subsidiaries of the Hochland Group. All third-party applications should be able to interact and communicate with each other ideally via the technologically adapted interfaces.

Cideon Taken on Board

Two further sub-projects ultimately emerged from this overall project, one for data migration and the other for integrating the CAD systems with SAP ECTR. "The project turned out to be much more complex than originally expected. Data migration in particular was a real challenge and became a critical success factor over time.” "We weren't able to migrate our database from SAP ECC 6.0 to SAP S/4HANA," said Volker Hanisch, Head of Procurement and S4F Project Manager for the entire Natec Network.

"The SAP ECTR interface was also causing us problems." Knowing that this was an ideal test environment for collaboration, Hochland Natec ultimately engaged Cideon as a consultant and software developer.

The goal: to get the best possible support in order to provide Hochland Natec employees with powerful digital tools in the future. "And we do this with a focus on our customers in the mechanical engineering sector - from the customer inquiry to the order and the entire life cycle of the machine up to its possible replacement by a next-generation machine," adds Hanisch.

Read more about the project between Hochland Natec and Cideon in the reference report:

Overview of SAP Interfaces

SAP & CAD Interfaces

Find out more about our SAP CAD interfaces and use data from the design department for subsequent processes in SAP.

SAP & PDM Interfaces

Discover our SAP PDM interfaces and connect your product data seamlessly with SAP.

SAP & 3DX Interfaces

Discover our SAP 3DX interfaces and benefit from seamless information and process synchronisation between Dassault Systèmes 3DEXPERIENCE and SAP.

How do you become a Cideon reference customer?

Are you currently working successfully with us on a joint project? Each of our customers is individual, has specific requirements and therefore very different solutions that are implemented. For us, every customer project is unique and should be valued just as much.

In our reference reports we focus on your company, the project highlights and your benefits.

Would you like to present your company and the joint project even more prominently? Then simply contact your responsible Cideon Account Manager and we will take care of all the further details for creating a reference report and publishing it on our website, blog and social media.