Integrated CAD-Data in Product Configuration

Suppliers and mechanical engineering companies are constantly adapting their strategies and processes to digitalization. The need for increasingly more product individualization requires standardization and modularization. Cideon Conify supports quotation and order processing for multi-variant products. This involves integrating sales configurations, automated CAD data, engineering-to-order and BOMs.

Gräfelfing, 20 February 2023: Interdisciplinary configuration in mechanical and plant engineering is becoming increasingly important to meet customer demand for individualized products at reasonable costs. It requires a high level of automation combined with close integration of all processes including order engineering. In large sectors of the industry, however, this is not yet standard practice for configurable products with engineering elements.

But a solution is available: Conify, developed by Cideon, part of the Friedhelm Loh Group. Conify automatically generates the configured product, a digital twin, as a CAD dataset and saves it in a PDM-compliant format. Engineering-to-order is then able to incorporate customized product adaptations at minimal additional effort. Order processing and production can then work with clear and consistent documentation, bill of materials and work plans. The result is a standardized, digital process, from sales to delivery, with maximum automation.

Configuration For Increased Added Value

An integrated approach to managing multi-variant products must cover the entire value chain – from product development, sales and engineering through to final delivery. Each sub-process requires consistent data management – with no deviations or redundancies. The basis for achieving this is established during product development through systematic product standardization and modularization, together with incorporation in product configurators and CAD models. This is the starting point for all subsequent steps.

Data and systems can then be used by sales to generate competitive quotations, which can be augmented by visualizations, drawings and CAD models. Cideon Conify automatically generates CAD-neutral product data, usually in simplified overview format, using the available parametric CAD data. If an order is placed, this data will then become more detailed. When creating the order, detailed product assemblies are generated from the parametric data. This enables full part masters and bill of materials to be created for any specific variant, while ensuring precision reuse of historical parts and assemblies.

Modifications are usually required for specific orders, and engineering will be able to locate the CAD data pre-generated by Cideon Conify in the PDM/PLM system. Further bill of material and article data result from this process step, which can then be used in company processes via standard interfaces. This is the basis for further value creation right up to the point of delivery.

Open For Integration

Cideon's consultants support businesses to achieve consistent and integrated configuration processes. Discovery Workshops are held to identify potentials for optimization. Specific implementation plans can then be developed based on realistic demo models. These define ways for lean processing in multi-variant product engineering.

Cideon Conify's modular concept enables different systems to be integrated and can be extended. Sales configurators such as SAP and FDU (Autodesk) are currently supported. For CAD systems, Autodesk Inventor and SolidWorks from Dassault Systèmes are among those supported. In PDM, the focus is on Autodesk Vault and SAP ECTR, but other interfaces can also be implemented.

Summary:

Cideon Conify takes configuration processes to a new level. It significantly reduces project lead times from customer inquiry to order placement, increases quotation quality and reduces repetitive tasks from the outset.

Further information: https://www.cideon.com/solutions/conify/

Reprint free of charge. Please indicate as source CIDEON Software & Services GmbH & Co. KG as the source.

We would be pleased to receive a voucher.

Images

With Cideon Conify, companies link data from the sales and engineering phases - for automated provision of PDM-compliant CAD data.

With Cideon Conify, companies link data from the sales and engineering phases - for automated provision of PDM-compliant CAD data.

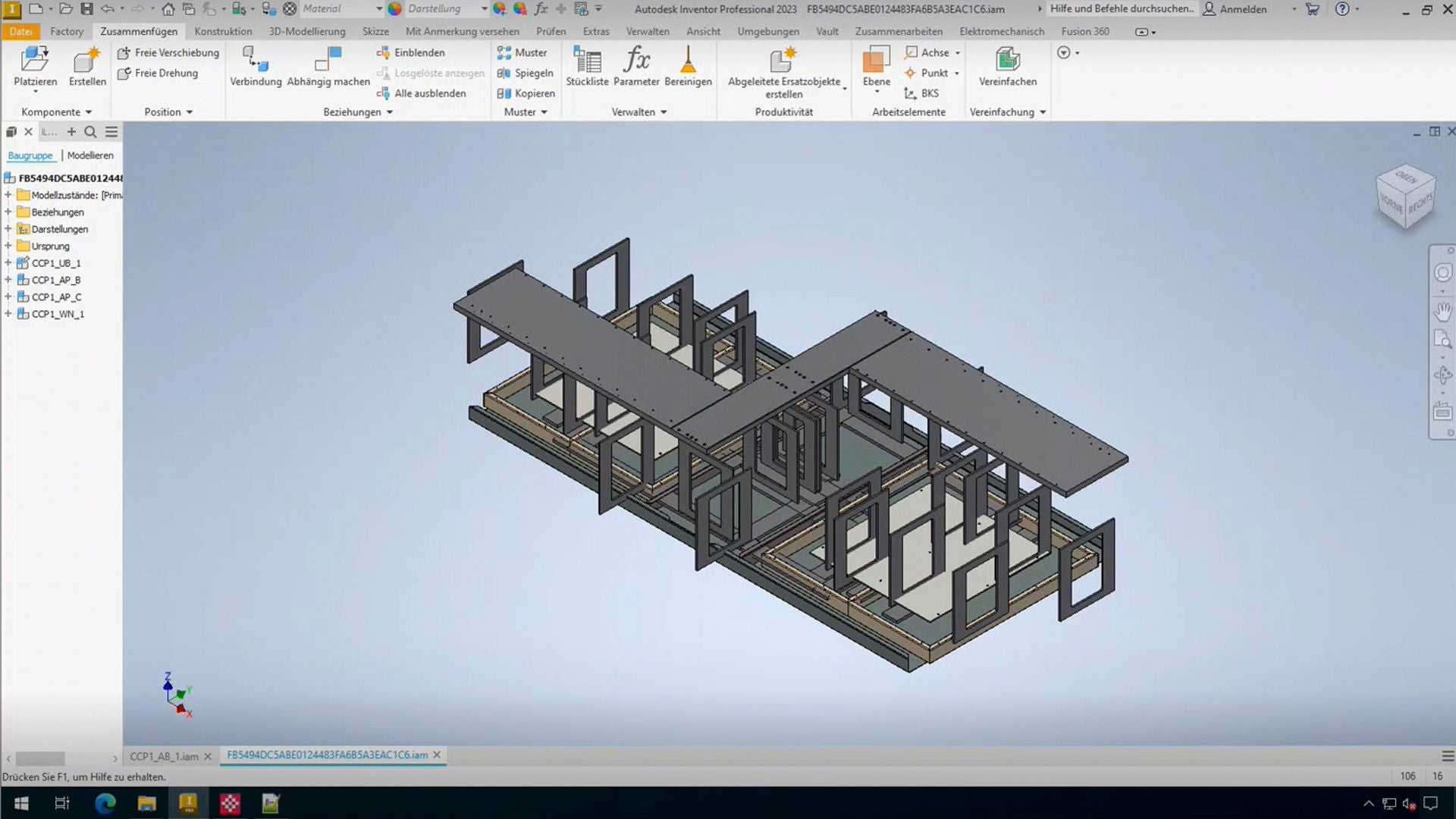

In the CAD system (for example Autodesk Inventor) the configuration data can be marked out and processed.

In the CAD system (for example Autodesk Inventor) the configuration data can be marked out and processed.

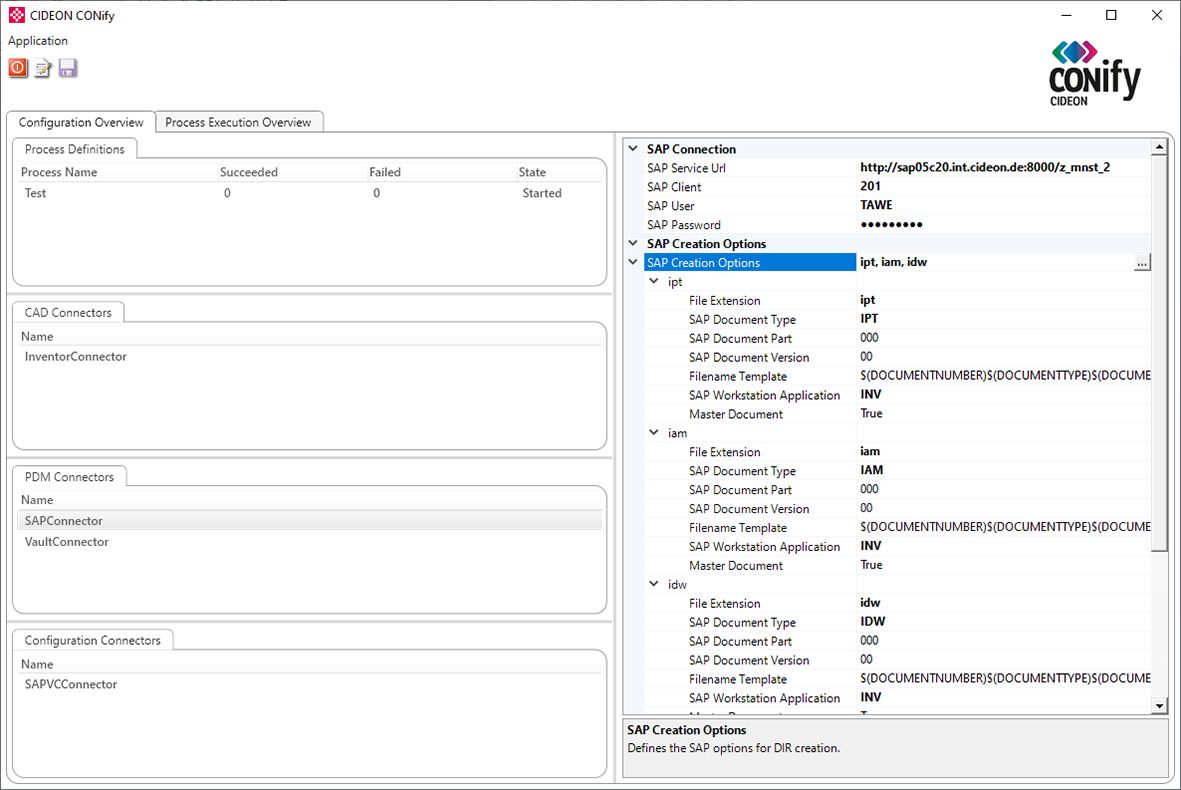

Cideon Conify with different setting options of the individual CAD and PDM connectors for use in the process.

Cideon Conify with different setting options of the individual CAD and PDM connectors for use in the process.

About Cideon

Cideon advises and supports companies in optimizing their product development processes – from the initial concept through to engineering, production and services.

Cideon's innovative solutions ensure continuous data flow along process chains making data accessible and cost-effective throughout the company. In this way, Cideon's customers can fully exploit the potential of digitalization to benefit themselves and their clients.

Cideon employs 310 staff at 13 locations in Germany and Austria. It is part of the Friedhelm Loh Group, a globally successful Group with 12 production facilities and 95 subsidiaries.

Further information can be found at www.cideon.com and www.friedhelm-loh-group.com.

Cideon's Latest Press Releases

-

Cideon has developed new interfaces for the integration of CAD and PDM systems with SAP PLM. Read more in our press release.

Cideon has developed new interfaces for the integration of CAD and PDM systems with SAP PLM. Read more in our press release. -

Read our press release to learn about the benefits of the closer partnership between Cideon and NTT DATA Business Solutions.

Read our press release to learn about the benefits of the closer partnership between Cideon and NTT DATA Business Solutions. -

At SPS trade fair we will be presenting our new Cideon Conify ECAD connection. Find out more in our press release.

At SPS trade fair we will be presenting our new Cideon Conify ECAD connection. Find out more in our press release. -

Cideon Sparify is the new solution for spare parts management. Find out more about the solution in our press release.

Cideon Sparify is the new solution for spare parts management. Find out more about the solution in our press release.