Packaging is multi-layered in more ways than one. It protects and presents the packaged goods, and informs customers about the contents, usage, and risks. Transport packaging often combines individual packages into larger units, providing additional protection during handling along the transport chain. This is important in the mail order business as well, where several million shipments are sent every day in Germany alone, and this number is growing.

Sustainable Packaging

Corrugated cardboard is one of the most widely used materials for transport packaging. As a lightweight material made entirely of paper, it is very stable, lightweight, and relatively easy to process and recycle. It is produced by gluing together smooth and corrugated paper webs together. The first patents for this process were granted in the USA at the end of the 19th century.

Today, a complex industrial process is used to process up to nine paper webs to produce corrugated board in numerous varieties with different corrugation types and combinations. Corrugators are usually almost 200 meters long and process paper from rolls several meters wide at speeds of over 450 meters per minute to produce corrugated sheets. They have a production capacity of over one million square meters per day.

Leading Solution Provider

BHS Corrugated Maschinen- und Anlagenbau GmbH is headquartered in Weiherhammer near Weiden in the Upper Palatinate region of Bavaria. It is one of the leading manufacturers of corrugated cardboard production systems. Since 1960, the company has designed and manufactured corrugated board machines, and it is now regarded as a leading solution provider in the corrugated board industry.

BHS Corrugated is a lifecycle partner to its customers, providing support from development and production to installation, maintenance, and innovative service solutions. As a full-service manufacturer of complex machines, BHS Corrugated develops and produces both the mechanical and electrical engineering of the mechatronic corrugators, as well as the software. BHS Corrugated has been using high-level programming language methods for some time to increase engineering efficiency.

Steps Towards Data Consistency

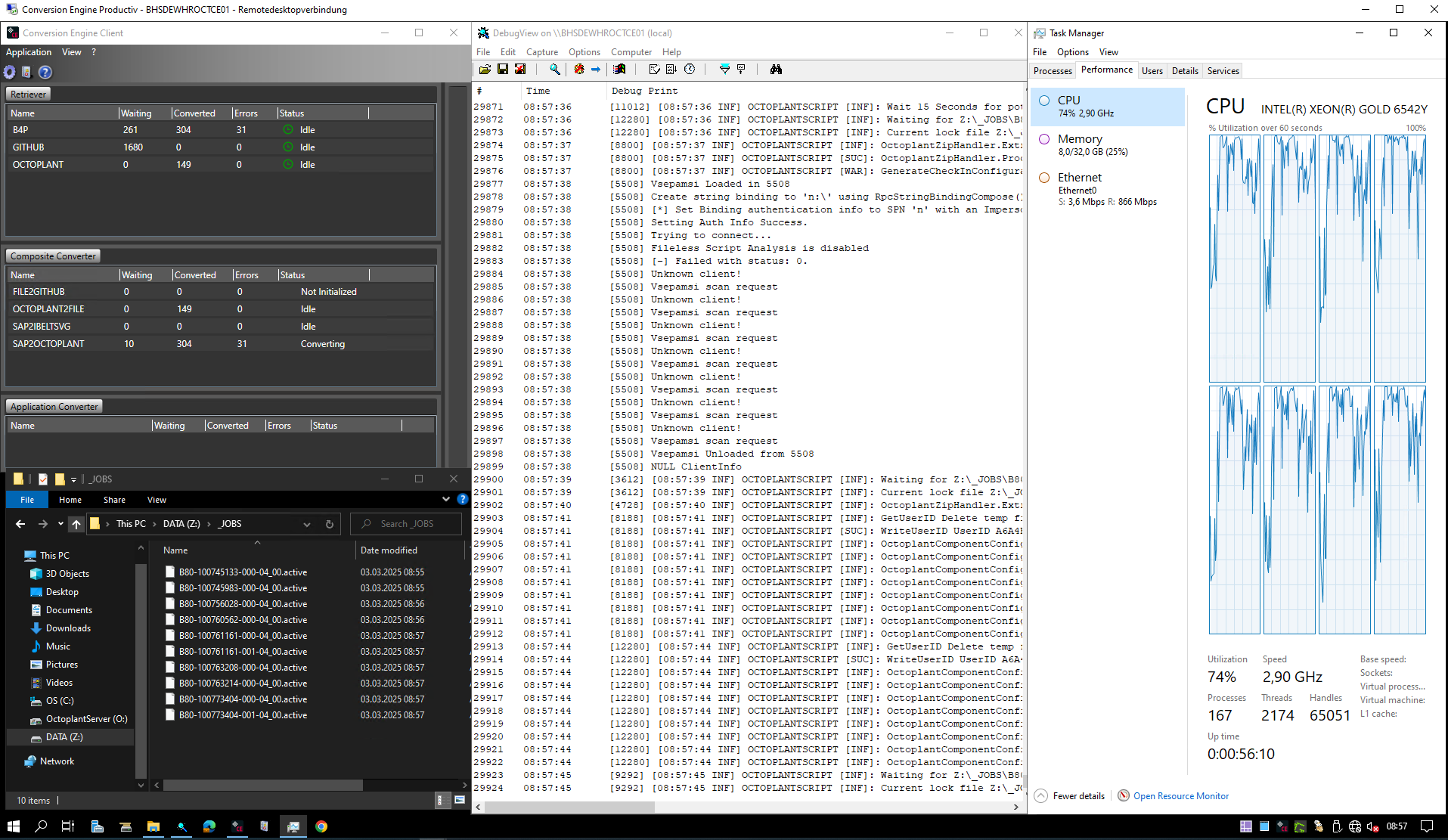

The company invested in digitalization for a long time, primarily to optimize process parameters, and improve automation levels, and increase production efficiency. For instance, BHS Corrugated employs the SAP Integrated Product Development (IPD) software solution to enrich mechanical engineering data with software, creating a comprehensive mechatronic system that is linked with business data from the ERP system.

Data from the various authoring systems is transferred via the SAP Engineering Control Center (ECTR) to the content repositories in the SAP system, which are distributed across two locations. Similar to the previous product, SAP PLM Interface to Solid Edge, this SAP-distributed solution is software from CIDEON Software & Services GmbH & Co. KG (Cideon).

Incorporate Software

BHS Corrugated decided to introduce a comprehensive versioning system for the machine software developed in-house, which made the need for more extensive use of the existing software tools evident. The goal was to meet to meet increasingly stringent requirements and provide the correct software version worldwide at all times.

The company chose for a market-leading product that can be used for both IT and OT. In addition to version management, the software offers functions for automatic backup and rapid restoration of the correct system configuration. This feature is crucial for large, customized machines with countless sensors and subsystems, most of which operate 24/7.

Newly created programs from the software engineering system are now transferred to the PLM system with qualified version information. This solution allows the SAP variant configurator to determine the correct variant and version, as well as the appropriated mechanical and electrical planning documents.

Read more about the project between BHS Corrugated and Cideon in the reference report:

How do you become a Cideon reference customer?

Are you currently working successfully with us on a joint project? Each of our customers is individual, has specific requirements and therefore very different solutions that are implemented. For us, every customer project is unique and should be valued just as much.

In our reference reports we focus on your company, the project highlights and your benefits.

Would you like to present your company and the joint project even more prominently? Then simply contact your responsible Cideon Account Manager and we will take care of all the further details for creating a reference report and publishing it on our website, blog and social media.